Kelheim’s premium tampon fibre Galaxy® has proven effective in sanitary pads: It can substitute up to 70% of the synthetics in ADL (Acquisition-Distribution-Layers) in feminine hygiene pads.

The amount of feminine hygiene waste is enormous – and often the time it takes for these products to degrade is hundreds of years longer than the lifespan of the woman who used it, because the synthetic components are not bio-degradable. Changing consumer behavior drives the need for

environmentally friendly yet safe alternatives.

The viscose hygiene fibres from Kelheim offer significant ecologic advantages: they are made from cellulose, which means they are based on renewable wood and they are fully biodegradable.

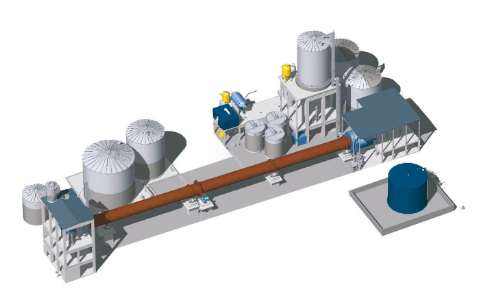

These fibres are manufactured exclusively in Germany, in one of the most environmentally friendly plants worldwide.

Galaxy® in sanitary pads offers not only a benefit for the environment. Due to its excellent wicking and absorption capacity it conducts liquids quickly and efficiently away from the body and leaves a pleasant feeling on the skin – in other words, it does exactly what the ADL layer is made for. In

addition, Galaxy® helps to distribute the liquid evenly in the absorbent core enhancing so the overall performance of the pad.

In comparison to other sustainable and conventional (synthetic) materials Galaxy® excels by

- faster acquisition

- lower rewetting

- enhanced distribution.

“Plastic must disappear from these single-use products. The substitution of single synthetic components in sanitary pads is the first step”, says Dominik Mayer from the Bavarian fibre expert’s

R&D team. “Down the road we want to offer a completely bio-based solution for sanitary pads and for various other hygiene applications.

Our advantage – besides the functionality of our patented Galaxy® fibre: Kelheim Fibres has been a renowned partner of the hygiene industry for decades; our production fulfils highest hygiene

requirements. We offer our customers fibres that are ideally suited for the specific needs of their products and their processes.”