To accelerate the world towards a zero-waste future, Walki is focusing on second generation dispersion-coated solutions.

“Our Walki®EVO dispersion coating portfolio is one of our main development programmes and focus areas. We are innovating a full portfolio providing barrier levels ranging from medium to very high for rigid as well as flexible fibre-based packaging”, says Annika Sundell, EVP Innovation and Business Development.

Most food items, especially those with a high fat content, need some form of barrier properties to hinder leakage. This barrier has typically been a plastic barrier, but separating the plastics from the fibre content is not always possible due to differing recycling infrastructure. This can be overcome with dispersion coating.

“We apply water-based barrier dispersion onto the paper to avoid fatty components from migrating into the packaging, causing visible staining. We are now using dispersion components that has been historically used in paper manufacturing in a novel way, and this significantly increases the recyclability of the packaging as we do not have separate the whole polymer structure as you have to do with a PE film”, says Andreas Rothschink, responsible for Business and Product Development at Walki.

Therefore, the consumer can throw the packaging in the bin for recycled paper as the amount of paper material in the packaging is up to 90%.

The Walki®Jazz solution has a barrier that is ideal for take away and fast food that you eat shortly after purchase.

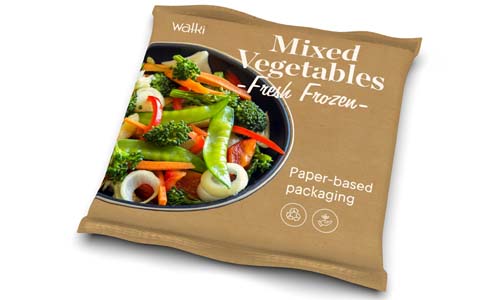

The Walki®EVO range comes with heat sealability properties, water vapour barriers and longer shelf-lives. The EVO range is also perfect for so called secondary packaging such as pouches containing already packed chocolate bars.

“The pouch needs mechanical strength and good runnability on packaging lines. That can all be achieved with Walki®EVO barrier papers”, says Rothschink.