Valmet will supply pulp production upgrade technology to PT. Tanjungenim Lestari Pulp and Paper (PT TEL) in Indonesia. The delivery includes an upgrade of continuous cooking system, with a design capacity of 1,800 air dried tonnes per day, and two sets of new automatic baling equipment. With the new investments, PT TEL targets to increase its pulp production capability and improve its pulp quality.

The order is included in Valmet’s orders received of the second quarter 2020. The value of the order will not be disclosed. An order with this scope of supply and delivery is usually valued in the range of EUR 10-12 million.

“Our target in the cooking system upgrade is to reduce our unit wood consumption by increasing the pulp yield and reducing reject content, to enhance our pulp quality and to lower the specific load on the recovery boiler. By upgrading to Valmet’s latest continuous cooking system we will significantly increase the pulp yield which will reduce our operating costs and allow us to be capable to increase the overall mill pulp production. Moreover, with the two new sets of baling equipment, we aim at improving availability and production stability. We have logically selected the advanced and reliable technology that supports us in achieving our target in this project,” says Hiroyuki Moriyasu, President Director, PT TEL.

“Valmet’s continuous cooking technology fits the customer’s requirement of cost-efficient pulp production with high pulp yield and low reject content, while also ensuring excellent pulp quality. Furthermore, this repeat order of baling machines shows that customer trusts our technology and our previous delivery of three baling machines in 2019 have met the customer’s expectation. We are happy to continue the cooperation with PT TEL,” says Fredrik Wilgotson, Vice President, Pulp and Energy, Asia Pacific, Valmet.

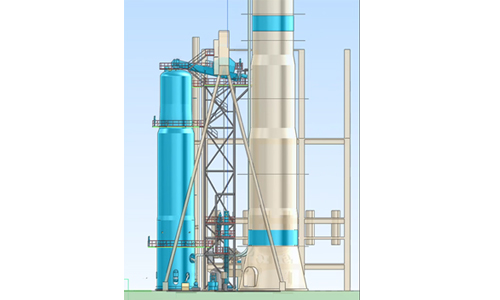

A new Valmet ImpBin will be installed prior to the existing digester vessel, which will be upgraded with Continuous Cooking G3 features.

Information about the delivery

This upgrade project will add the Valmet Continuous Cooking G3 technology to PT TEL’s existing cooking system. A new Valmet ImpBin will be installed prior to the existing digester vessel, which will be upgraded with Continuous Cooking G3 features. ImpBin ensures homogeneous chip steaming and impregnation, which is the key to produce high quality pulp with high pulp yield and low reject content. The upgrade also includes Valmet’s latest technology for chip pumping. The start-up is scheduled for the fourth quarter of 2021.

In addition, the delivery includes a modern Valmet Wire Tyer, which is operated by electrical servo motors, resulting in exact and gentle wire feeding. The Valmet Wire Tyer ensures a reliable system for bale wire application that can process up to 300 bales in an hour. The new baling equipment is scheduled to be delivered in late 2020 and the startup is planned for the first quarter of 2021.