Valmet is to supply an OptiWin Drum two-drum base winder to Jingxing Holdings’ board machine PM 3 in Malaysia. The target of the investment is to have high-capacity winding technology that meets the requirements of the board machine. The start-up of the winder is scheduled for 2026.

The order is included in Valmet’s orders received of the first quarter 2025. The value of the order will not be disclosed.

“We wanted a supplier that can offer us advanced winding solutions supported by strong references and technical expertise. We chose Valmet because their winders are equipped with technologies necessary for high-capacity board manufacturing,” says Liao Changlv, Vice General Manager, Jingxing Paper.

“The customer wanted a supplier capable of providing proven and advanced winding technology – our OptiWin Drum two-drum base winder helps them reach their long-term investment targets. This project strengthens Valmet’s position as the preferred supplier for high technology winders and will further enhance our long-term partnership with the customer,” says Ville Savolainen, Sales Manager, Board and Paper Mills, Paper business line, Valmet.

Delivery’s technical information

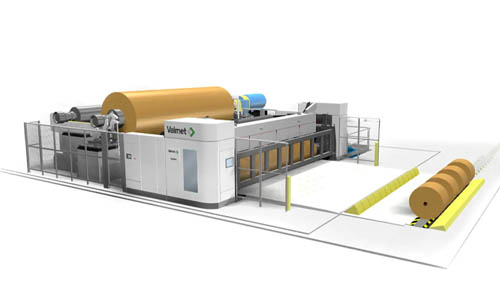

Valmet’s delivery will include an OptiWin Drum two-drum base winder with automatic functions such as set change with core and tail gluing and slitter positioning, an OptiCart Stream parent roll cart, and horizontal transfer rails. The delivery will also include spare parts packages and Valmet Industrial Internet solutions with connectivity.

The winder will handle parent rolls with a width of 8,660 mm at a design speed of 3,000 m/min. The PM 3 produces kraft top test liner and recycled liner grades with a design basis weight from 70 to 200 g/m2.