Valmet will supply a new high-capacity winder to Gascogne Papier in France. The winder will be delivered for the paper machine PM 7 at their Mimizan site. The start-up of the machine is scheduled for 2025.

The order is included in Valmet’s orders received of the second quarter 2023. The value of the order will not be disclosed.

“This winder will be a key contributor to the top-level quality of our future papers, which will reinforce the current positioning of Gascogne Papier as a world leading kraft paper producer,” says Régis Laffont, Industrial Director, Gascogne Papier.

“To meet their high capacity and quality targets, the customer was searching for a supplier capable of providing a high-quality winder. Our solution and expertise reassured them and confirmed that we are a frontrunner in the winding technology,” says Yannick Duperrier, Senior Mill Sales Manager, EMEA Area, Valmet.

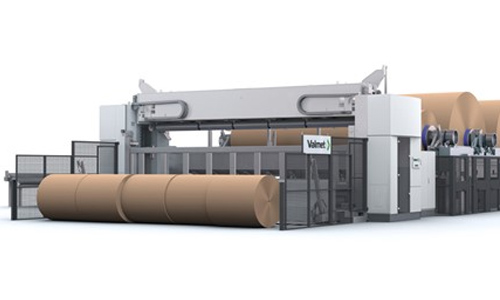

Valmet’s delivery will include a high-capacity OptiWin two-drum compact winder that has a wide production range with different widths and diameters of shipping rolls. As a key solution for high-quality multi-roll winding, the winder is equipped with pro-active dual spreading.

The winder is also equipped with an automated butt-joint splicing for achieving the customer’s high-capacity targets. In addition, the delivery will include a wide site service for easier project handling, maintenance master data, Slitter Management Program, a spare parts package, and Valmet Industrial Internet solutions, such as Valmet Winder Diagnostics.

PM 7 produces natural machine-glazed and sack kraft paper grades. The new winder will handle parent rolls with a width of 6,870 mm and a diameter of 3,200 mm. The paper machine’s design speed is 1,300 m/min and the daily design capacity is 450 tons.