Valmet introduces new control product called Valmet Stand-Alone Retention Control (Valmet RET) for retention and break-time headbox ash consistency management. It offers benefits for paper, board and tissue makers previously only available to the users of Valmet DNA process control and Valmet IQ quality control system.

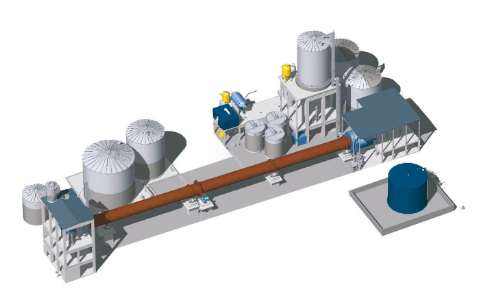

Utilizing the Valmet Retention Measurement (Valmet RM3), low consistency measurement and control hardware with state-of-art model predictive control, the product enables users to take control of the wet end to a new level.

“Both controls, based on the Valmet IQ MD Optimizer, already have a proven track record. We know that by stabilizing the wet end we can offer improved quality, chemical and energy savings as well as better runnability for virtually all grades,” says Timo Rantala, Product Manager, Automation, Valmet.

Active wet end management for stability and runnability

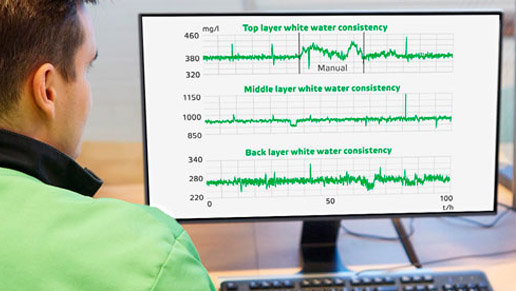

Valmet Stand-Alone Retention Control improves paper quality in the machine direction by reducing variations in basis weight, paper ash and moisture. Additional advantages include fewer wet end breaks, savings in chemicals and drying steam as well as better control of grade changes and start-ups – all leading to higher productivity.

As the very first pilot user of Valmet Stand-Alone Retention Control mentioned: “Retention measurement and control are fully reliable solution, which both are used all the time. We can say they are standards at our paper machine.”

The goal of Valmet Stand-Alone Retention Control is to minimize consistency variations within the short circulation and stabilize wet end operation. It stabilizes white water consistency by controlling retention aid flow.

The goal of breaktime headbox ash control is to keep paper web ash content stable and thus make web threading easier, breaktime shorter and paper ash on target right after sheet break. Breaktime headbox ash consistency control becomes automatically operational during sheet break.

Both controls reside in Valmet hardware installed in the cross-connection room. This enables fast deliver, short implementation and tuning time of the control product in the mill. A secure remote connection to Valmet RET allows a fast response and remote help from Valmet locations around the world. Connection to mill system can be made with standard 4.20 mA I/O signals or optional digital links.