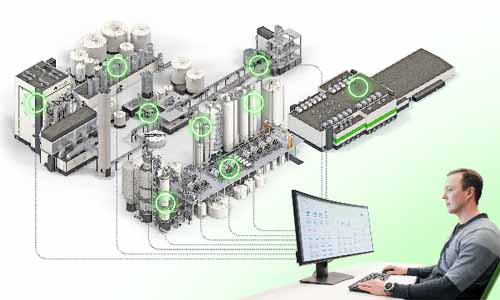

Valmet introduces Mill-Wide Optimization (MWO) to enhance overall pulp and paper mill profitability. With Valmet MWO, production teams can boost the mill’s performance by making well-informed decisions across different process areas towards shared goals.

The optimization observes the entire mill balance in real-time and considers both the current and future states of the mill. As a result, suboptimization of individual processes that do not align with mill goals can be avoided. MWO also provides the ability to balance environmental sustainability with production, quality, and cost.

“The pulp and paper industry is transitioning towards self-governing autonomous operations and towards a younger workforce with new roles and responsibilities. Valmet MWO helps to capitalize on these changes and unlock the mill’s full potential,” says Greg Fralic, Product Manager, Mill-Wide Optimization, Automation Systems business line, Valmet.

Optimizing production, quality and costs at a mill-level

Mill-wide production planning helps mills to keep up with the daily changes in production bottlenecks. Valmet MWO reflects the mill’s current state and maximizes production subject to existing and projected bottlenecks, while stabilizing the process and balancing pulp and liquor inventories.

Mill-wide quality planning helps attain the desired final product quality while keeping the costs low. It adjusts the quality targets at each step from chip to finished product.

An audit as the first step towards mill-wide optimization

To move away from optimizing individual processes, pulp and paper mills need to be evaluated as a whole. Valmet Mill-Wide Optimization Audit helps to reveal the true production potential and the corresponding return on investment. Based on historical data, the audit helps to evaluate production increase potential, identify limitations, and highlight use cases of mill-wide optimization. It also helps to uncover development opportunities required for moving towards fully optimized operations.