Valmet will supply recycled fiber lines for Umka Cardboard Mill rebuild in Serbia. The order is a continuation of Valmet’s board machine rebuild delivery, which will be started up during the second half of 2021. The main target of the rebuild is to increase the customer’s production capacity and improve end-product quality. The recycled fiber lines are scheduled to start-up during the first half of 2022.

The order was included in Valmet’s orders received of the first quarter 2021.

“We are delighted that an end-to-end solutions provider like Valmet is supplying us with the recycled fiber lines for our cardboard mill rebuild. Umka has an 82-year long history and with the ability to increase our capacity to over 200,000 tons, while also improving our recycled cardboard products, this equipment perfectly positions us for continued success in the future,” says Milos Ljusic, Umka’s Managing Director.

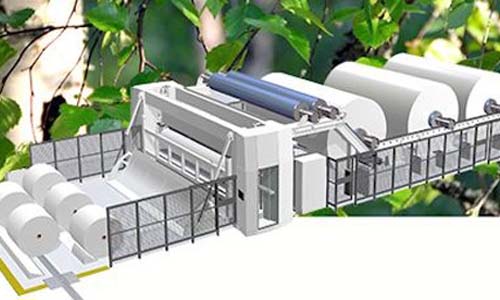

Valmet’s delivery will include substantial changes to the recycled fiber lines for Umka’s paper machine PM 1. These include an Old Corrugated Containers (OCC) line with reject handling and a rebuild of two Deinked Pulp (DIP) lines.

“Together with the customer, we built a solution that will help Umka increase recycled fiber lines capacity, reduce maintenance, and improve end-product quality. We’re happy to be able to provide services, technology, and the industry expertise as an end-to-end partner for Umka,” says Hanna Jokinen, Director, Capital Business, Paper business line, Valmet.