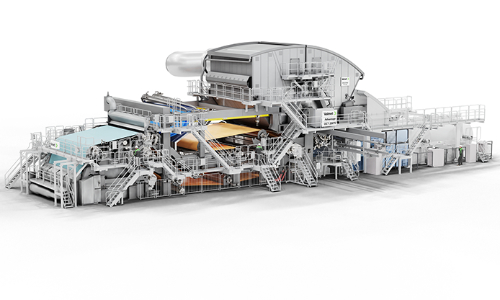

In 2018, UPM announced the conversion of Paper Machine 2 in Nordland, Germany, from fine paper to specialty grades. The conversion is currently ramping-up. The agility of the paper machine enables production of a wide range of products driven by sustainability, such as glassine, kraft and barrier papers. The annual designed capacity of Nordland PM2 is 110,000 tonnes.

”With the help of new capacity from UPM Nordland in Germany, we can support our customers’ sustainability goals even better. UPM Specialty Papers can help replace non-renewable materials with recyclable solutions from sustainably managed forests. The new capacity from Nordland will further improve availability of our most recent innovations for labelling and packaging. Customers also have access to a stable supply of paper from UPM’s extended network of world-class mills”, says Jaakko Nikkilä, Executive Vice President, UPM Specialty Papers.

Our customers benefit from UPM Nordland’s renewable and recyclable products

UPM has created a unique concept for release liner recycling, which will help promote a circular economy within the labelling value chain. Collected release liners are de-siliconised and used to produce new high-quality release liner base papers. With these products customers can supplement their sustainability offering.

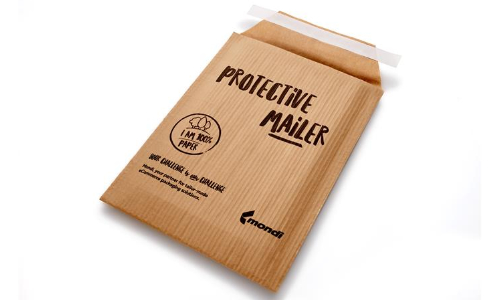

To help customers’ transition to more sustainably designed packaging, UPM is developing recyclable barrier papers for more demanding end-uses, such as food packaging. We have also introduced a portfolio of kraft papers for the packaging segment. These papers can replace non-renewable and difficult-to-recycle materials in many applications.