One man and his dog. A few years ago, this was the prediction of a major paper machinery supplier describing the workforce that would be required to run a paper mill in the future thanks to automation, digitalization and artificial intelligence. We are not quite there yet.

At the Fastmarkets RISI Conference in Lisbon this week, a full session was dedicated to “The Mill of the Future”. A recent survey produced by McKinsey evaluates an average potential gain of 15% in productivity for the mills implementing the latest technological solutions available.

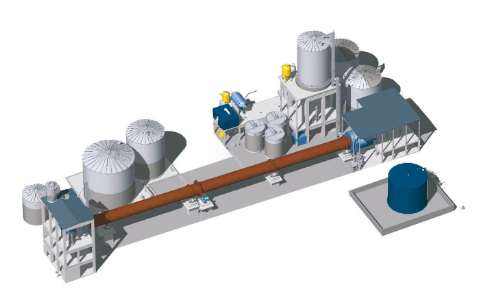

Voith and Valmet are obviously at the forefront of the what might become Industry 5.0, by developing optimized processes through data analysis, machine learning and prediction tools.

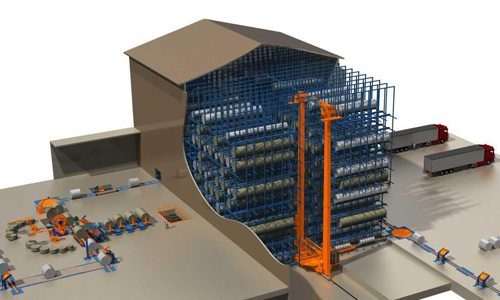

Another interesting aspect of intelligent technologies lies in the logistics part of the value chain. In that respect, the Finnish company PESMEL has developed a solution of fully automated distribution centers, with a sophisticated warehousing design supported by a powerful management and communication software. A presentation by Tony Leikas, CEO of PESMEL, showed the audience through business cases, how Metsä Board in Finland and SAICA in Spain managed to optimize their logistics, with significant financial savings and a reduced environmental impact expected.