Ensuring feedwater pump reliability through proactive site performance testing

Feedwater pumps are the heart of any steam generation process and as such, they are considered critical assets. When viewed from the cardiologic perspective, feedwater pump criticality becomes patently obvious, without a healthy, reliable heart, the process will degrade and eventually cease to function. Just as an electro-cardiogram provides a medical expert with valuable performance data on the human heart during a stress test, field pump performance testing provides the expert with developed head, capacity and efficiency data under normal (or abnormal) operating conditions.

Chris Muscavage, Field Technical Service Engineer, at Sulzer, looks at the importance of pump performance testing and how it can improve plant reliability.

Fossil fuels continue to be the primary source fuel for power generation which, according to the U.S. Energy Information Administration in 2017, accounted for 62.7% of capacity with nuclear capacity accounting for an additional 20%. This equates to nearly 83% of U.S. power being wholly or partially reliant upon steam generation utilizing feedwater pumps.

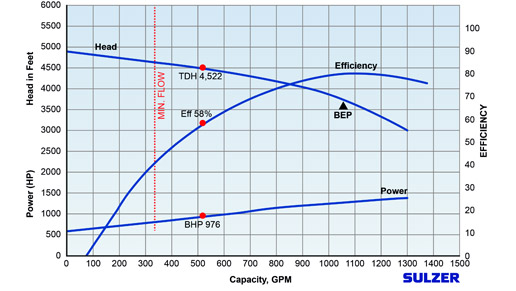

Deregulation has given rise to an open market where pump “design point” and actual “operating point” may no longer be equivalent and may vary significantly. Such market-driven conditions primarily affect combined-cycle, coal, and biomass-fueled generators during Independent System Operator (ISO) dispatch control. Where is my pump operating? Which pump should take overhaul priority? These are certainly valid questions regarding asset availability, reliability and the associated financial consequences of “abnormal operation”.

Where is my pump operating?

In the following example, one boiler feedwater pump (BFP) was selected from a group of eight where proactive field performance testing was accomplished. Performance testing was employed to provide the owner/operator with quantifiable pump condition data to aid in prioritizing unit overhaul schedules. This particular generation facility is configured with six separate combined-cycle units employing 12 feed water pumps. The example pump is one of eight axial-split, multi-stage, ring-section pumps. At the time of field performance testing, gross facility generation was limited by ISO dispatch to 60 percent of full generator / heat recovery steam generator (HRSG) load.

In addition, in cases where the pump’s NPSHr curve rises with a reduction in capacity, the NPSHa may be insufficient to overcome the on-set of cavitation. Operation at lower than recommended BEP flows can result in pump inlet flow recirculation leading to increased vibration, wear and reduction in mean-time-between-repairs (MTBR).

Which pump should take overhaul priority?

Pump mechanical integrity is also evaluated in addition to hydraulic testing with real-time vibration data being captured and analyzed. BFP C1 vibration response showed clear indication recirculation at the suction side and BFP C2 exhibited similar response to a lesser degree. Vibration data were consistent with pump hydraulic results and leak-off rates. The facility prioritized overhaul scheduling accordingly.

Further mechanical evaluation is accomplished using infrared thermal imaging, visual inspection of pump, seals, lube oil system, coolers, baseplate, foundation, and grouting.

In taking this comprehensive approach to pump performance testing from both the hydraulic and mechanical perspectives, an experienced field engineer is able to then provide the end user with detailed analyses and recommendations relative to in-service pump performance.

Field performance testing of critical feedwater pumps provides the owner/operator with quantifiable results and recommendations for their pump(s) in service at plant generation conditions. Proactive periodic testing raises the reliability bar another notch by establishing a benchmark for comparison which removes any question of pump condition. Annual or bi-annual performance testing of a facility’s heart is highly recommended.