The Canadian tissue producer Kruger Inc. made three simultaneous announcements last week:

- Its Kruger Products subsidiary is announcing a $240M project to expand its operations in the Sherbrooke region which will become a major hub for the production of tissue products in Québec;

- Its Specialty Papers division will receive financial contributions totalling $146.1M; and

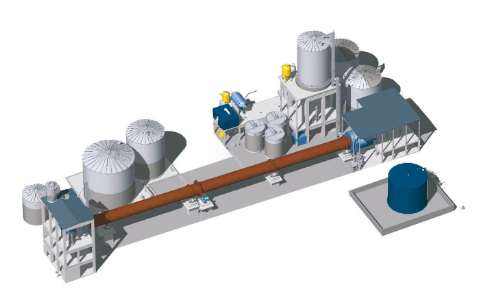

- Kruger Products celebrated the completion and successful start-up of its state-of-the-art manufacturing facility in the Brompton borough of Sherbrooke, featuring Canada’s largest and most modern through-air-dry (TAD) tissue machine after investments of $575M.

These announcements were made during a press conference held in the presence of Mr. Pierre Fitzgibbon, Minister of Economy and Innovation, and Mr. David Angel, Executive Vice President and Chief Financial Officer of Kruger Inc., and with the virtual participation of Ms. Geneviève Hébert, Member for Saint-François and Deputy Government Whip, and Mr. Joseph Kruger II, Chairman of the Board and CEO of Kruger Inc.

Together, these investments and financial contributions total $961.1M and will lead to the creation and retention of 376 jobs in the Sherbrooke region, as well as protect 267 jobs related to the Kruger Wayagamack plant in Trois-Rivières, Québec.

The new investments and financial contributions totalling $386M were financed in part by the Government of Québec through Investissement Québec which is providing $165M in loans and contributing, as a partner, $34.8M in the recapitalization of Kruger Specialty Papers L.P.

“Our investment at Kruger will enable the Company to modernize and strategically reposition the Brompton Plant. The manufacturing complex will now focus on the fast growing tissue product market. Part of our pulp and paper sector needs to modernize and renew its infrastructure throughout our regions. We need more projects such as this one to revitalize our pulp and paper industry and to continue fostering economic development in Québec,” said Mr. Pierre Fitzgibbon, Québec Minister of Economy and Innovation.

TAD tissue plant start-up: Mission accomplished

Kruger Products also celebrated the completion of construction and successful start-up of its state-of-the-art Sherbrooke manufacturing facility featuring Canada’s largest and most modern through-air-dry (TAD) tissue machine. The Sherbrooke facility also comprises three converting lines which have been successfully commissioned.

“I congratulate everyone involved in building our new Sherbrooke Plant,” said Dino Bianco, CEO of Kruger Products. “Considering the circumstances of the pandemic, it was an incredible feat to complete this massive project on time and on budget. It makes me very proud to be part of this organization and to be surrounded by dedicated and resourceful people who thrive on innovation and are committed to excellence. On behalf of the entire Kruger Products team, I would like to extend a warm welcome and congratulations to the 180 new employees who have joined our team.”

At maturity, the TAD tissue machine will increase the annual output by 70,000 metric tonnes of bathroom tissue and paper towels for the Canadian and American markets.

The Québec government, through Investissement Québec, also supported the construction of the new tissue plant by granting a $105M loan to Kruger Products Sherbrooke Inc. in 2018.

$240M expansion project

Kruger Products announced today its plan to expand its operations in the Brompton borough by adding an LDC tissue machine and two converting lines to be built and commissioned over the next three years. LDC, which stands for light dry crepe, is one of the most widely used tissue making technologies in the world. At maturity, the new LDC machine will increase Kruger Products’ annual production capacity by at least 30,000 metric tonnes of tissue products for the Canadian and American markets.

The LDC machine will be housed in a new building to be constructed on a site adjacent to the new TAD tissue plant. The new LDC plant will include a facial tissue converting line, while a bathroom tissue converting line will be added to the converting facility that was built as part of the TAD project. The two additional converting lines will be commissioned successively in 2022 and 2023, and the LDC machine is expected to start up a year later, in 2024.

In addition to creating 169 jobs, including 141 at Kruger Products, the expansion project will bring significant benefits to the region in terms of direct spending estimated at $110M and close to 410,000 person-hours of work for the construction.

The additional production capacity will enable Kruger Products to expand its product offering and grow its market share across its different categories, including bathroom tissue, paper towels and facial tissue for household and away-from-home use. These are available to consumers under such favourite brands as Cashmere®, SpongeTowels®, Scotties® and Purex® in Canada, and White Cloud® in the U.S.