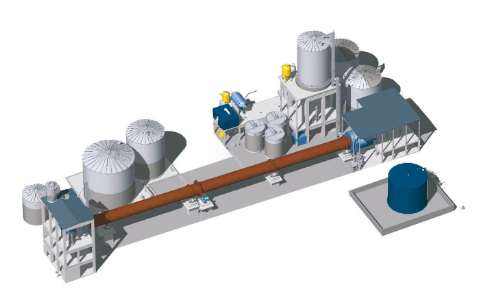

Runtech just released the news of SpinDrive’s successful integration of Runtech’s RunEco EP 1000 Turbo Blower with the cutting-edge Active Magnetic Bearing solution at a prominent Turkish paper mill by Ankutsan A.S..

The collaboration between Runtech Systems and SpinDrive has resulted in a significant advancement in industrial efficiency and sustainability. By combining Runtech’s expertise in turbo blower technology with SpinDrive’s state-of-the-art Active Magnetic Bearings, the RunEco EP 1000 Turbo Blower delivers unparalleled performance and reliability, contributing to enhanced productivity and reduced energy consumption in the dewatering process.

A Seamless Collaboration Leads to Exceptional Outcomes

The journey of Runtech Systems and SpinDrive began several years back. It all started with some research and development projects led by LUT University in 2016, exploring the use of active magnetic bearings. After successfully testing these bearings, Runtech decided to use them in one of their turbo blowers, the RunEco EP1000.

SpinDrive looked carefully at what Runtech needed and made changes to the system to fit those needs. Working together, Runtech found a partner in SpinDrive who could offer a controller for their bearing design and help with setting up the system completely.

“In this project, we began by testing the impeller at various operation points to evaluate the customer’s energy efficiency. With the active magnetic bearing system and Magma X800 AMB controller, we efficiently tested the system and gathered data for impeller redesign. As a result, the updated impeller boosted the system’s efficiency, ensuring reliable operation throughout the turbo blower’s entire range,” explains Alexander Smirnov, CTO and co-founder of SpinDrive.

Unlocking the Benefits of Active Magnetic Bearings for Turbo Blowers

“We are thrilled to see our RunEco EP 1000 Turbo Blower thriving with SpinDrive’s Active Magnetic Bearings solution in the Turkish paper mill. With the help of active magnetic bearing solutions provided by SpinDrive, our customer is able to improve their energy efficiency substantially. AMBs enable having subcritical rotor system with full operational capacity from 0-100% speed while fluid film bearings would yield to supercritical rotor and very limited operational range” said Ville Lahdensuo, R&D Director at Runtech Systems. “Another significant benefit of AMBs in the pulp & paper application is the robustness against impeller build-up. “

The RunEco EP 1000 Turbo Blower offers a range of benefits, including:

- Improved energy efficiency: The integration of SpinDrive’s Active Magnetic Bearings enables a wide operational speed range leading to energy savings and lower operational costs.

- Increased reliability: Active Magnetic Bearings technology eliminates the need for lubrication and bearing maintenance.

- Environmental sustainability: Replacing liquid ring pump with turbo blower brings energy and water savings and minimizes environmental impact. Thus, RunEco EP 1000 Turbo Blower greatly supports eco-friendly manufacturing practices.

Aleksi Salmi, Development Engineer at Runtech Systems, found great satisfaction in contributing to the commissioning project in Turkey.

“We are incredibly proud of the successful commissioning of the RunEco EP 1000 Turbo Blower, made possible through the seamless integration of Magma X800 AMB controller and complementary software solutions, coupled with our team’s extensive experience. The combination of Magma X800 AMB controller and advanced software played a crucial role in ensuring a smooth and efficient commissioning process. With its robust capabilities and intuitive interface, Magma provided us with invaluable insights and control over the turbo blower’s performance, allowing us to fine-tune and optimize its operation to perfection. Moreover, our team’s rich experience and expertise in the field further complemented the commissioning process, enabling us to overcome any challenges with ease and precision. This successful collaboration underscores the importance of cutting-edge technology and seasoned professionals in delivering exceptional results.”

Teamwork Triumph: A Win-Win Strategy through Successful Cooperation

“We are delighted with the fruitful cooperation between SpinDrive and Runtech Systems. Through our collaborative efforts, we have successfully leveraged our expertise in Active Magnetic Bearings technology to enhance the performance of Runtech’s RunEco EP 1000 Turbo Blower. With over a year of rigorous testing and knowledge sharing, we have developed a deep understanding of each other’s systems, allowing us to address our customer’s needs efficiently and effectively.” said Alexander Smirnov, CTO and Co-founder at SpinDrive.

“This turbo unit for vacuum creation stands out as an unparalleled product, with no direct competitors in sight. It makes this solution absolutely unique. With over a year of rigorous testing and knowledge sharing, we have developed a deep understanding of each other’s systems, allowing us to address our customer’s needs efficiently and effectively,” Alexander continued.

This is a great example of using Active Magnetic Bearings for turbo blowers in operational environment. We believe that our tailored magnetic bearing solutions can help our customers to provide the highest value to the end users.

For more information about Runtech’s RunEco EP 1000 Turbo Blower and SpinDrive’s Active Magnetic Bearings technology, please visit Runtech Systems or SpinDrive.