The Swedish chemical textile recycler re:newcell has made its first sale of circular dissolving pulp to an Asian viscose manufacturer. The sale marks an important step in the commercialisation of the company’s breakthrough recycling technology for cotton and cellulosic textile waste.

“As far as we’re aware, this is the first delivery of its kind in the world. A true breakthrough for us and for the fashion industry as a whole” says Mattias Jonsson, CEO at re:newcell.

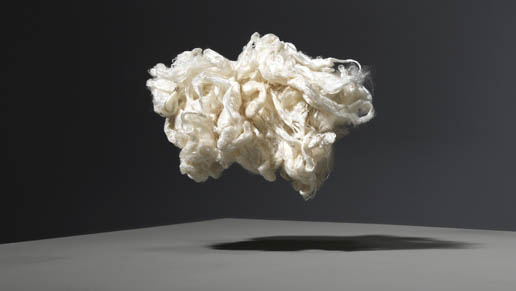

The 22 ton shipment of its branded Circulose™ dissolving pulp was produced at re:newcell’s plant in Kristinehamn, Sweden using both postconsumer and postindustrial cotton waste without any virgin material added. It will be used to manufacture virgin quality viscose staple fiber for commercial retail fashion applications.

“Fashion brands are catching up to a shift in consumer demand towards sustainable raw materials. That demand pull is now finally cascading back in the value chain to the fiber producers that we’re talking to” Mr. Jonsson adds.