Metsä Group’s objective is that it will no longer use any fossil fuels in its production by 2030 and will therefore not produce any fossil carbon dioxide emissions.

Even now, renewable energy plays a key role in Metsä Group’s operations. In 2021, 90 per cent of the fuel used in Metsä Group’s production was fossil-free, consisting mainly of wood-based production side streams.

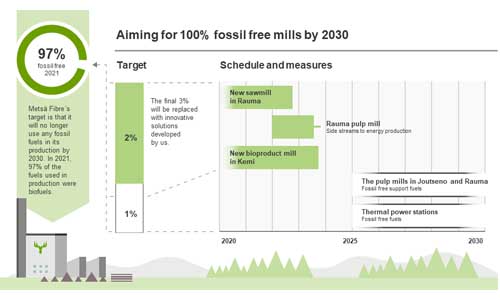

Investments like the Kemi bioproduct mill and the Rauma sawmill play a significant role in Metsä Group’s journey to fossil-free production. As a rule, new mills and production lines are designed to be fossil-free. In Rauma, the synergies provided by the integration of the sawmill and pulp mill will also be used for energy production and side stream utilisation.

Plenty of energy from pulp mills

Metsä Fibre is proceeding step by step towards fossil free operations. In 2021, 97 per cent of the fuel used by Metsä Fibre in its production was biofuels.

A significant share of all renewable energy produced in Finland is generated in connection with pulp production when the black liquor formed from wood material and cooking chemicals is combusted in the recovery boiler. The energy self-sufficiency rate of Metsä Fibre’s pulp mills was 151 per cent in 2021, and they are among the largest producers of renewable energy in Finland. In addition to our own production, we supply renewable energy in the form of district heat to local communities and as electricity to the grid.

With the fossil-free Äänekoski bioproduct mill, Metsä Fibre took a major step towards fossil-free operations. Another example is the Joutseno mill, where the lime kiln is fired by product gas made from bark. At the same time, the design of the Kemi bioproduct mill is based on an electricity self-sufficiency of 250 per cent.

Alongside the share of bioenergy, Metsä Fibre is focusing on energy efficiency and energy saving. The more energy is saved and the more efficiently energy is produced – for example, by using secondary heat or production side streams – the more renewable energy can be supplied outside the mill.

RELATED NEWS

Piero Celli passed away at 89

April 25, 2025

Papeteries de Vizille launch of the Iripack Pure range

April 24, 2025

Every tree tells a story — and this one represents ours.

April 22, 2025

Voith Paper completes the PM2 rebuild at Panasa in Ecuador

April 17, 2025

Sylvamo Announces CEO, CFO Transition Plan

April 17, 2025

SCA to increase kraftliner prices by € 60 per tonne

April 16, 2025