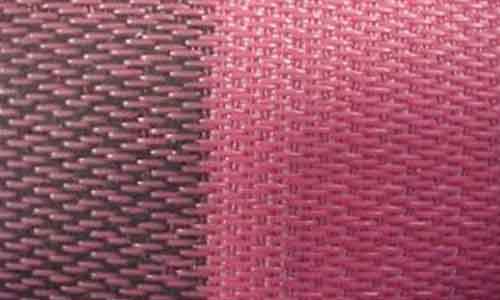

ProJet BV have successfully started up two (2) Cleaners at Greif Board in Massilon, OH, USA. PM1 produces Medium Board (23-33# at 2,500fpm), using 100% OCC. OCC is known for its extreme contamination on the 1st and 2nd Dryer Sections. The Power Cleaner is highly effective in maintaining cleanliness and permeability of Dryer Fabrics which is exactly the reason that Greif chose ProJet.

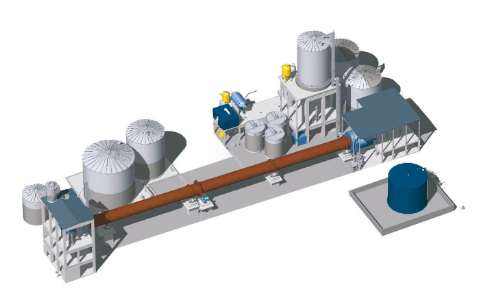

A Power Cleaner is a continuous cleaning device for Dryer Fabrics. The Power Cleaner uses a single traversing head that cover the fabrics using up to 14 ruby nozzles at a pressure of maximum 500 bar (7,500psi). Air knives and a Venturi-vacuum-system make sure all water and debris is effectively discharged into a save-all and from there, outside the machine.

Applying a ProJet Cleaning Solution guarantees consistently clean dryer fabrics from beginning to end of usable dryer fabric life. Consistently clean fabrics deliver the following significant manufacturing advantages:

·No chemical cleaning will be required to maintain fabric cleanliness.

·No shutdowns will be required for fabric cleaning. This will provide increased manufacturing productivity and profitability.

·Maintaining consistently high dryer fabric air permeability increases available dryer capacity.

·Better CD moisture profiles will be maintained.

·Sheet curling, caused by uneven drying, will be eliminated.

·Dryer fabric life will be substantially improved.

·Much less contamination will be deposited on dryers, doctor blades, and felt rolls.