On December 15, 2021, Saad Nader defended a doctoral thesis from the Université Grenoble Alpes prepared under the supervision of the Professor Evelyne Mauret (Grenoble INP-Pagora / LGP2) and of the Professor Nicolas Brosse (Université de Lorraine / LERMAB). He presented the results of his research entitled NanoSteamEx: production of microfibrillated cellulose by steam explosion.

Micro and nanofibrillated cellulose (MNFC) exhibits remarkable properties with high added value applications in various fields. In recent years, there has been a growing interest in lignin-containing micro and nanofibrillated cellulose (L-MNFC) produced from different lignocellulosic materials. However, current L-MNFC production processes are energy-intensive, which limits their use.

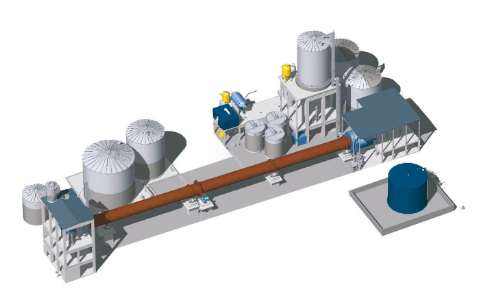

Steam explosion (SteamEx) is an efficient lignocellulose pretreatment process, accessible on an industrial scale. The objective of this study is to propose an energy-efficient and environmentally friendly process, involving pre-treatment by SteamEx, in order to manufacture L-MNFC from beech wood and Eucalyptus globulus bark, then used for the production of nanopapers and the reinforcement of wood adhesives.

The originality of this study is twofold:

- L-MNFC with different lignin contents are produced from beech wood and eucalyptus bark (two understudied biomasses for MNFC production, in particular eucalyptus bark).

- The cooking step of the raw material (pulping) was carried out in a SteamEx apparatus combining the effects of alkaline delignification and explosive defibration. Pulping was followed by a refining and a grinding step. The chemical composition, morphology and mechanical properties of the produced L-MNFC gels and nanopapers have been studied.

The results demonstrated the possibility of producing L-MNFC by SteamEx. They have a quality comparable to that of L-MNFC produced by conventional processes (involving chemical and/or enzymatic treatments) while benefiting from a shorter reaction time. SteamEx promotes the detachment of lignin from the fibers by forming spherical nanoparticles dispersed in the L-MNFC gels.

- The L-MNFC produced from eucalyptus bark are formed of nanofibrils with diameters between 5 and 100 nm and coarser elements. With quality indices of ≈ 60, they are used as reinforcements in Urea-Formaldehyde adhesives to improve the mechanical properties of particleboard.

- The L-MNFC produced from beech wood presents quality index between 60 and 80. They are used to produce nanopapers with Young’s moduli of 8 – 9 GPa.

RELATED NEWS

Best wishes for 2026 from the PaperFIRST Team

January 1, 2026

LATAMPAPER Buenos Aires – A must attend event in 2026

December 18, 2025

Elof Hansson appoints Lennart Eberleh as new CEO

December 17, 2025

Toscotec starts-up PM5 tissue line for Saudi Paper Group in Saudi Arabia

December 17, 2025

Rottneros President and CEO Lennart Eberleh has resigned

December 12, 2025

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

December 12, 2025

GardaMatt Ice: Lecta’s new coated paper for premium publishing

December 12, 2025

SCA on CDP’s sustainability A-List 2025

December 10, 2025

Adestor Collect & Recycle teams up with SOPREMA to promote recycling

December 9, 2025

Billerud invests in the next level of fluting performance at Gruvön

December 9, 2025