For its second Technical Day of the year organized on June 12, the Technical Association of the French Paper Industry (ATIP) chose, once again, a theme at the heart of the life of paper factories: decarbonization. In total, some fifty people attended this event. Around ten paper mills were represented by one or more people (Ahlstrom Arches, Fibre Excellence, Gascogne, GPC Papier & Carton, Papeteries Léon Martin, Rayonier AM (RYAM), Sterimed, SWM Saint-Girons and Sylvamo).

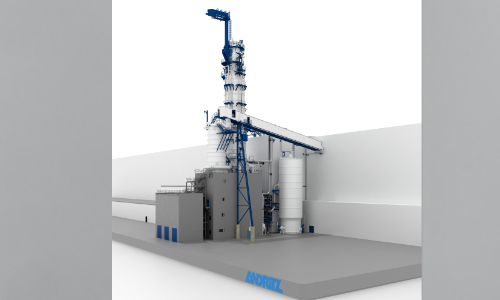

This event began on June 11 with a visit to the RYAM-Avebene factory in Tartas, which has decarbonized its process thanks to an investment of some €38 million, which allows it to produce second-generation biofuel (bioethanol) from Landes pine. A first in France and the third in Europe.

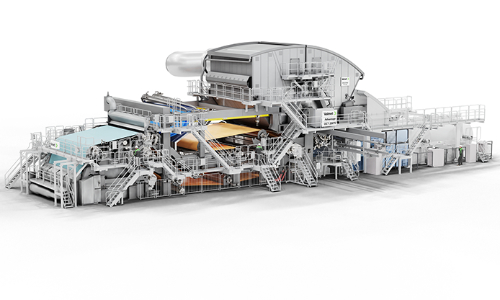

The next day, organized in Mont-de-Marsan, was very busy with around ten speeches. After an overview, carried out by Copacel, of regulatory developments and explanations on how to evaluate the carbon footprint, the presentations made it possible to discover the numerous technical possibilities available to paper manufacturers to optimize their energy consumption or improve their carbon footprint. EDF and Dalkia have described the advances made possible by the very high temperature heat pump with a first installation in operation on the Wepa Greenfield site. For their part, STX and Naldeo presented technical solutions and possible financing to reduce energy consumption. Siemens Energy presented the potential offered by hydrogen combustion turbines (with the example of Hyflexpower currently implemented at Smurfit Kappa Saillat). ABB and Valmet also described the range of their solutions that maximize energy savings and meet sustainability commitments. On this decarbonization subject, bearings are not left out as SKF‘s presentation showed, both in terms of this company’s own decarbonization process and the solutions it offers to paper mills. Feedback on a Solid Recovered Fuels power plant project currently being finalized in Condat (Lecta group) was also explained by Impulse (E-nergys group) while Kurita described its Dropwise® steam condensation technology (with applications in dryers), which improves heat transfer and reduces energy consumption. Finally, Interis provided an update on its solutions for valorizing liquor from the pulp process into 2G cellulosic bioethanol as a decarbonization tool with the example that started at RYAM-Avebene.

Valérie Lechiffre