Global technology group Voith will be working with Munich-based technology and software company PerfectPattern in future in the field of artificial intelligence. The aim of the alliance is to optimize processes and planning in industrial production environments based on the latest artificial intelligence technologies developed by PerfectPattern. Voith will contribute the expertise it has acquired in more than 150 years of working

in the fields of paper production, hydropower and drive technology.

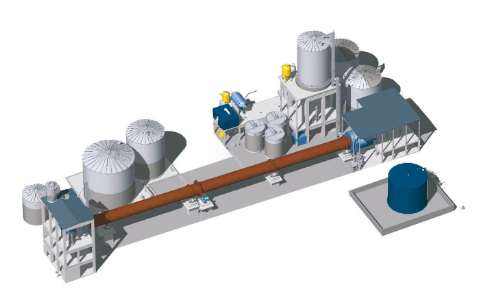

The first pilot projects under the cooperation agreement will be in the paper industry. Voith paper machines are used for a considerable proportion of global paper production. Paper manufacturers are facing certain challenges in the production environment, including increasing operating costs, rising expenditure on energy and fresh water, and the stability of raw material supplies. Technology group Voith works with its customers on an ongoing basis to improve the production processes for paper manufacturing. In future, the company will also use the Pythia technology platform developed by PerfectPattern. In the production process, the technology helps ensure the optimum setting of all parameters on a continuous basis, from the raw material mix to process control and the machine itself.

“PerfectPattern’s technology is groundbreaking for our goal of using AI as a key component of our customer solutions,” says Dr. Roland Muench, CEO of Voith Digital Ventures. “Because the PerfectPattern approach allows the relevant process parameters to be both predicted and optimized.”

PerfectPattern, Voith’s partner in this venture, has its headquarters in Munich. It develops technologies in the field of artificial intelligence that optimize and control industrial production processes. In this conjunction, the

corresponding software solutions make particular use of “reinforcement learning” in combination with intelligent prediction models. In doing so, PerfectPattern takes a step beyond the application of neural networks and optimizes them mathematically and methodologically. Whereas conventional prediction models entail significant development and adaptation effort and the input of huge volumes of data, the PerfectPattern system learns by itself, so to speak, and does so with even less input. This substantially reduces the development effort.

“In industry in particular, artificial intelligence can make a huge contribution to optimizing processes and saving considerable resources,” says Fabian Ruechardt, CEO of PerfectPattern. “The printing industry is already successfully using our technologies to improve print scheduling and thus increase competitiveness. With Voith, we have a strong partner in future with whom we can develop other segments like paper manufacturing, for example.”