Aikawa Fiber Technologies Oy, a leading supplier in the pulp and paper industry, is expanding its business. Alongside the manufacture of equipment and spare parts, maintenance and service operations will be added to its core functions. The hub of the expansion is the approximately 1,500 square meter Service Center completed in Varkaus at the beginning of the year. The investment will also relieve the congestion of the existing factory and allow the development and expansion of operations.

“The industry focuses on its core competencies. Replacement, maintenance and lifecycle monitoring of spare parts are not the core competencies of the paper and pulp industry – they are outsourced to experts. Here we have a foot in the door. We have the know-how and now there is a place for the screen work to be done. We are very excited”, says production manager Kari Varpunen.

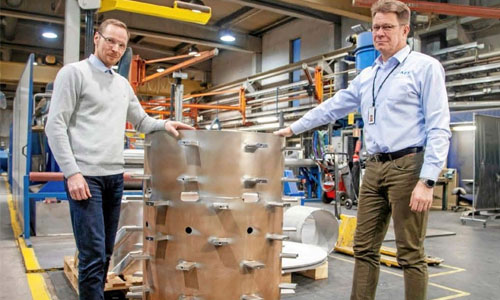

“We have always wanted to compete as a full service provider. Over the past 20 years that I have worked at AFT, the quest has always been to be the best”, says customer service manager Jarkko Naumanen.

In Varkaus, wear components are mainly made for equipment used in the pulp and paper industry: screen cylinders, rotors and plates for fiber separation. The Service Center provides mills with, among other things, proactive maintenance, equipment lifecycle monitoring and technical support on site.

“For example, we can see from our monitors what the condition of the customer’s equipment is and tell them that we should plan to change the bearings in April”, Naumanen describes.

The customer is offered added value and durable, refurbished products. At the same time, energy consumption and carbon footprint are reduced. Naumanen and Varpunen praise their products as “Mercedes Benz of spare parts”

“If the customer saves 30 percent in energy consumption when buying an AFT rotor, it pays off, even if the part is a little more expensive initially.”

Jarkko Naumanen was given the task of planning a new business in 2019. Maintenance services have so far been provided on a small scale, but the scale is now different. Twelve worker have been assigned to the Service operations and, depending on the situation, will also work in the current plant. The equipment assembly will now also move to the new building. “About 15 employees is a realistic goal”, Kari Varpunen estimates. “They will need to be replaced in current activities, which we also hope to grow.”

“The new premises were built by Keski-Savon Teollisuuskylä Oy, to which the City of Varkaus granted a loan of EUR 2.5 million. The role of the city was an important part of the whole project, with which the investment was obtained in Varkaus”, says Kari Varpunen.

“There is room for growth on the site. Additional investments in the original production facility are moving forward, including investments to further reduce the carbon footprint of production”, says CEO Risto Weckroth.

Demand for paper has been on a steady decline. However, AFT believes in and invests in the future. Paper machines are being converted to board production and new targets are opening for wood fibers. The increasing use of recycled fiber also causes equipment wear and requires more durable parts.

“The global pandemic has slowed more new equipment purchases than spare parts, but there may be a significant surge ahead when this pandemic finally relaxes”, Varpunen believes. “It may be that we are expanding at a good time.”