Ence – Energía y Celulosa, the Spanish pulp and energy producer, is considering launching a new project, complementary to its Pontevedra biofactory, in the A Coruña town of As Pontes. This is a bioplant for the recovery, development and production of new biomaterials, with which the company enters the paper recovery sector, as part of its strategic commitment to the circular bioeconomy.

Ence wants to be part of the future of Galicia and, therefore, redoubles its commitment, building a bioplant complementary to the Pontevedra biofactory, for the development of new biomaterials from recovered fibre and cellulose produced in Pontevedra. The aim is to “complete the circle” in Galicia: to manufacture a product whose origin and destination is northwest Spain and which is marketed primarily in Galicia.

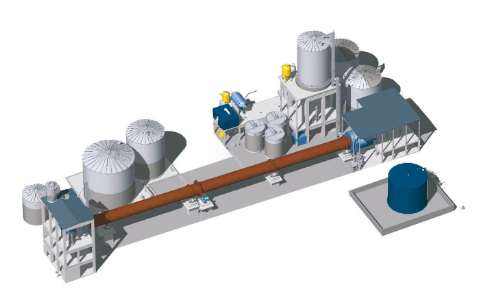

This bioplant is not a cellulose plant, but will produce recycled natural fibres, with a consumption of natural resources (water, agroforestry by-products, etc.), capacity and dimensions much smaller than those of the Pontevedra biofactory. It is an independent work centre, with an autonomous and differentiated activity.

The process, from its launch (including engineering and obtaining all the permits) will take between three and five years, until its start-up. It will involve a combined investment of around 355 million euros and the creation of some 1,190 jobs (150 direct, 400 indirect and 636 induced).

The complementary bioplant will turn the area into a strategic enclave for the bioeconomy in Galicia, as it proposes the transformation of a thermal power plant into a modern facility that will be an example of Just Transition in the Community. This initiative is in line with the company’s other projects to convert plants linked to the “old economy” into facilities for the new circular bioeconomy.

The natural fibres that this bioplant will manufacture will be obtained from 80% recovered paper and cardboard, in a process that is fully respectful of the environment, in which it will be bleached with an innovative eco-efficient and chlorine-free process.

Eighty per cent of the plant will thus be focused on the production of bleached recycled pulp. The remaining 20% will be dedicated to the production of toilet paper and recovered paper rolls. The company is considering collaborating with Galician companies in the sector as part of a Circular Economy Industrial Pole in Galicia.

The process will be fully sustainable from start to finish, based on reusing and minimising the use of natural resources. Thus, the water used by the bioplant can be reused. The use of the best available technologies will also ensure that the small amount of water that is returned to nature will be of the highest environmental quality, purer than when it was collected.

The plant itself will generate all the renewable thermal and electrical energy required for the process, using agroforestry by-products certified in a pioneering manner under the European SURE scheme for biomass and in accordance with the Decalogue for the sustainability of biomass as a fuel – an initiative promoted voluntarily by Ence.

In this way, the bioplant will be energy self-sufficient. Paper production will be completely carbon-free. No fossil fuels will be used in any step of the process, which reinforces the cutting-edge nature of this facility.