Century Pulp and Paper recently made a successful start-up of their new Valmet Advantage DCT line in the Lalkua mill in India. It is their second Valmet tissue line, but also the first tissue line in India that is equipped with the Advantage ViscoNip press technology.

“We are excited to have the second Valmet tissue line up and running in our Lalkua mill in India. In Century Pulp and Paper, we constantly develop the mill with latest technology to ensure premium tissue quality to our customers and at the same time reduce the environmental impact. We are the first company in India to install a tissue line equipped with the Advantage ViscoNip press technology. Valmet’s flexible and result oriented approach has also been an important part to achieve a successful start-up” said Mr. J.P. Narain, CEO, Century Pulp and Paper when the company started up their second Valmet Advantage DCT tissue machine at the mill in Lalkua, India recently.

“We congratulate Century Pulp & Paper to a successful startup of their new Valmet Advantage Tissue Machine”, says Christine Jung, Valmet MC Project Manager.

“We appreciate the excellent cooperation between Valmet- and Century teams who jointly achieved this important step forward”, says Varun Jain, Director India Region, Valmet.

”This tissue machine startup constitutes an important landmark in the region, further strengthening Century Pulp and Paper as a leading tissue manufacturer. We are proud of our close and successful cooperation with Century, who require the highest performance and world leading tissue technologies, says Tomas Karlsson, Sales Director, Valmet.

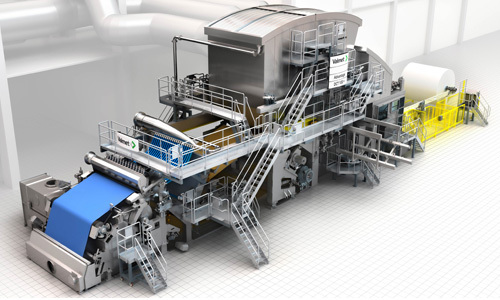

Technical information about the delivery

The new tissue Advantage DCT 100HS tissue machine, TM7, is 2.85 m wide with a design speed of 2,000 m/min. The machine is equipped with an OptiFlo headbox and a 16 feet Yankee cylinder. It is also featured with the Advantage tissue technologies AirCap and Air system, a SoftReel A reel, ViscoNip press and ReDry energy saving equipment. The machine is also equipped with a Valmet Focus Rewinder. The production line is optimized to save energy and enhance quality of the final product.