ANDRITZ has received an order from Guangxi Sun Paper to supply two tissue machines for its new mill in Beihai City, Guangxi Province, China. Start-up is planned for 2021.

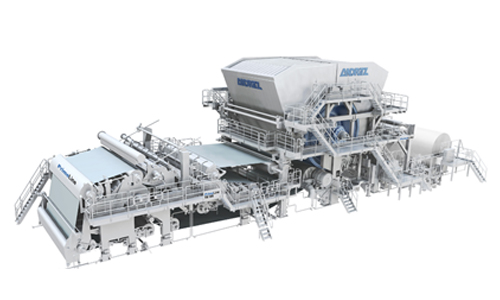

The ANDRITZ tissue machines are of the type PrimeLineTM W 2000, with a design speed of 2,000 m/min and a working width of 5.65 m. They are equipped with a large suction press roll, an 18 ft. PrimeDry Steel Yankee with head insulation, and a re-evaporation system, thus enabling energy savings. The scope of supply also includes FibreSolve FSV pulpers, the paper machine approach flow systems, broke handling and fiber recovery, and automation systems (QCS, DCS).

In July 2019, Sun Paper established a wholly owned subsidiary – Guangxi Sun Paper – to build an integrated pulp and paper mill in Beihai. For this mill, ANDRITZ was awarded the supply of pulp dewatering and white liquor plant technologies, key process equipment, and a chemi-thermomechanical pulping system in June 2020. The new greenfield mill in Beihai will eventually have a total pulp and paper capacity of 3.5 million tons annually and will be constructed in two phases over approximately five years.

The present order underlines the strong partnership that Sun Paper and ANDRITZ have in tissue. For the production site in Shandong province, ANDRITZ has already delivered two tissue production lines with tissue machines, stock preparation and automation that have been in operation since 2014 and 2015, respectively. This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the Chinese tissue industry and ANDRITZ’s expertise specifically in wide tissue machines and resource-saving components like steel Yankees.