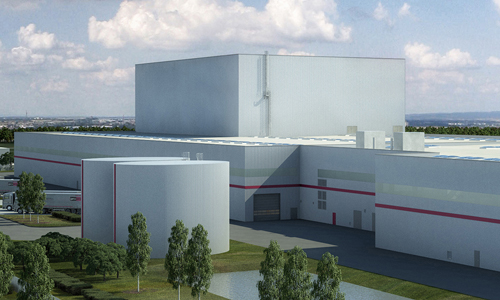

Progroup, one of Europe’s leading manufacturers of containerboard and corrugated board from Landau in der Pfalz (Germany), has been operating its PW12 corrugated sheetfeeder plant, one of the most efficient and high

performing plants anywhere in the industry, in Ellesmere Port, England since January 2019. The company is now investing in the infrastructure at its site and the packaging manufacturer Krystals is investing in production facilities. A total of 20 million pounds (around 22 million euros) is being invested in expanding the site to create a packaging park.

The packaging park will combine Progroup’s high tech corrugated board plant with the specialist packaging production that Krystals provides. This will deliver the maximum level of efficiency in the production processes. In addition, the two cooperation partners are consistently implementing their sustainability strategy by using technology that conserves resources and reducing CO2 emissions.

Strong partners: Grow successfully together

Progroup consistently remains on a growth trajectory. This is based on long term, trusting cooperation arrangements with independent, medium sized packaging manufacturers. The Ellesmere Port site plays a crucial role here. Progroup invested more than 80 million pounds in the high tech plant, which opened in 2019, and this sum is now being increased again with the construction of the packaging park. “With the packaging parks model, Progroup’s objective is to grow together with its customers in order to further expand its position in the market. We are absolutely delighted that we are able to continue this success story at the Ellesmere Port site with our long standing partner Krystals,” says Jürgen Heindl, Chief Executive Officer of Progroup.

Successful packaging park model: Efficient and environmentally friendly

The packaging park is being constructed over a total area of around 16,000 square metres and will be completed in the 2nd half of 2020. The production and IT systems of the two partners will be interconnected. This will significantly increase flexibility and efficiency. “Carefully coordinated technical equipment and tried and tested warehousing and logistics management deliver maximum reliability of supply. We can handle urgent needs at short notice more easily and with a quicker response through flexible interaction. Thanks to our cooperation with Progroup, we will be able to strengthen Ellesmere Port as an important production site. Our head office will remain in Lincoln,” says Arron Shingdia, Managing Director of Krystals.

High tech corrugated sheetfeeder plant with a focus on sustainability

The association reflects the sustainability strategy of both companies. “In the future, corrugated board which is conveyed via a bridge link to Krystals will require neither means of transport nor any packaging. In 2021 alone, we will thus save around 1,800 truck journeys. We will thus achieve a considerable reduction in noise and CO2 emissions,” says Maximilian Heindl, Chief Development Officer and member of the Board of Progroup.

The corrugated board grades which are manufactured in Ellesmere Port are what are known as Next Generation® products, which are manufactured entirely from recovered paper. They are noted for having a lower weight while retaining the same strength. This means that warehousing costs can be kept low and fewer shipments by truck to customers outside the packaging park are necessary.

State of the art technology for maximum efficiency

With a working width of 3.35 metres, the corrugated sheetfeeder plant is able to manufacture 235,000 tonnes of corrugated board per year. A series of new developments delivers a very high and constant working speed of 400 metres a minute. This speed is possible thanks to the highly automated control system for the whole plant. The state of the art high bay warehouse with 14,500 storage spaces is operated virtually autonomously for example with four automatic storage and retrieval machines. The employees receive the latest operating information live on wearables that resemble smartwatches either presented as graphics or via the headset. And the quality control is also done in automated fashion using the “Board dimension control”. This system performs the measurement check and ensures that the corrugated board sheets have a quality level that is 100% reliable.

Key facts about Progroup’s high tech corrugated sheetfeeder plant in Ellesmere Port

Total investment: Over 80 million pounds

Products: Single wall and double wall Next Board® corrugated boards

Annual production: 500 million square metres of corrugated sheetboard

Operating speed: 400 m/min

Working width: 3.35 metres

Warehouse type and capacity: Fully automatic high bay warehouse with more than 14,500 storage spaces and four storage and retrieval machines

Jobs: 45 high tech jobs operating in three shifts

Commissioning: 1st quarter of 2019