ANDRITZ has received an order from Bracell to supply energy-efficient and environmentally friendly pulp production technologies and key process equipment for Bracell’s Project “STAR” in Lençóis Paulista, in the state of São Paulo, Brazil. Start-up is scheduled for the third quarter of 2021. Award of this contract to ANDRITZ was announced in July 2019, however the name of the customer remained confidential at that time.

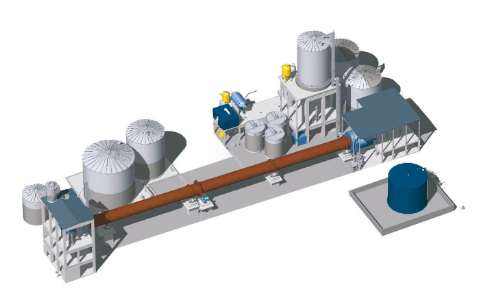

ANDRITZ will provide four of the six most important process islands in the pulp mill, which are to be supplied on EPCC (Engineering, Procurement, Construction and Civil Construction) basis:

- A complete Wood Processing Plant using ANDRITZ’s proven technologies and including chipping lines, stacker-reclaimer, chip screening, biomass handling with ANDRITZ BioCrushers, and biomass storage. Each chipping line for eucalyptus processing consists of ANDRITZ’s unique horizontally fed HHQ-Chipper (EXL model), ensuring high capacity without compromising on chip quality. Woodyard operation is enhanced with state-of-the-art ANDRITZ IIoT products, including ChipperEKG, stone detection, the ScanChip chip analyzer and a FlowScanner, which measures the density and moisture content of the chips to optimize the fiberline process.

- An ANDRITZ HERB Recovery Boiler with high steam parameters of 101 bar(a) and 515°C to maximize power generation. The HERB Recovery Boiler features energy-efficient flue gas cooling and feed water preheating technologies to maximize steam production for power generation. It is designed for extended operating periods without requiring wash water. At the beginning of December 2019, ANDRITZ successfully completed assembly of the first Recovery Boiler column.

- Environmentally friendly hardwood Fiber Lines that ensure low-effluent emissions, can produce both kraft and dissolving pulp, and which also include a chip feed system, LoSolids continuous cooking system with Pre-Hydrolysis Vessel (PHV), screen room and bleach plant, as well as ANDRITZ’s DD-Washer technology, ensuring low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality. The cooking plant for the fiberline is state of the art in the continuous cooking process for production of dissolving pulp.

- A new innovative EvoDry Pulp Drying System with energy-efficient pulp drying based on the high-capacity Twin Wire Former technology, with airborne dryers, cutter-layboy and baling lines. The approach flow with cleaner systems ensures homogeneous pulp feed to the subsequent process stage for both types of pulps – dissolving and kraft. The pulp dewatering machine comprises a headbox with dilution control, a Twin Wire Former, and a press section with one combi-press and two shoe presses. The ANDRITZ technology for pulp drying is very well proven all over the world. In addition, the ANDRITZ EvoDry sheet dryer is the most energy-efficient of its kind. Finally, the reliable ANDRITZ cutter-layboy provides the pulp bales to be further processed in the high-capacity baling lines, where the final pulp bale units are produced.

RELATED NEWS

LATAMPAPER Buenos Aires – A must attend event in 2026

December 18, 2025

Elof Hansson appoints Lennart Eberleh as new CEO

December 17, 2025

Toscotec starts-up PM5 tissue line for Saudi Paper Group in Saudi Arabia

December 17, 2025

Rottneros President and CEO Lennart Eberleh has resigned

December 12, 2025

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

December 12, 2025

GardaMatt Ice: Lecta’s new coated paper for premium publishing

December 12, 2025

SCA on CDP’s sustainability A-List 2025

December 10, 2025

Adestor Collect & Recycle teams up with SOPREMA to promote recycling

December 9, 2025

Billerud invests in the next level of fluting performance at Gruvön

December 9, 2025