Gambini delivers TOUCHMAX.AIR to Byness Company: the quality of the TouchMax embossing enhanced by AirMill technology!

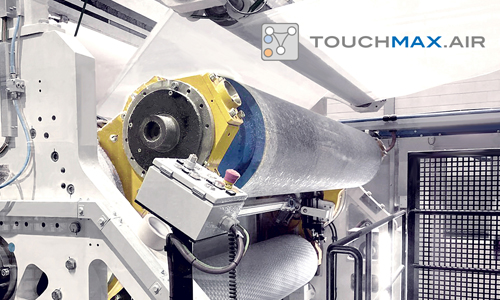

This new version, born from the integration of the TouchMax.Twin embosser-laminator with part of AirMill technology, allows to transfers more bulk to the tissue paper while maintaining its high quality values in terms of softness, absorbency and tensile strength, and also making the products more stable during the production phase, thus optimizing the efficiency.

TOUCHMAX.AIR works at a production speed up to 600 m/min and is characterized by extreme flexibility, being able to laminate in 5 different configurations: Synchronized, Random, LNG (Laminated-Non-Embossed), Point-to-Point and Point-to-Flat.

Thanks to this innovative machinery, Byness will be able to increase its range of products by satisfying the most diversified requests of Buyers, reducing production times and costs. Furthermore, the customer will be able to use less raw material and resources by using conventional papers (DCT/LCT), while obtaining, however, a product very similar to textured paper.

Byness S.r.l. is a tissue converting company which has been present on the tissue market for over 50 years and collaborates with the main groups in the sector.

Today, the Company is on the market with the brands Ninfea, EcoLine, Morbida and Naturel and has recently decided to renew most of its machinery in order to reach the highest production and quality standards.

Therefore, Byness has chosen Gambini’s FLEX 600 converting line: a 600 m / min consumer line equipped with the innovative, flexible and versatile TOUCHMAX.AIR embosser-laminator; a new important milestone in Gambini technology!