The Bolivian tissue producer Copelme (Compañía Papelera de Industria y Comercio Mendoza S.A.) has renewed its confidence in Valmet by investing in a new Perini MyGo line to increase production capacity, currently at 95%, at its historic Cochabamba plant in Bolivia. Integrating Perini MyGo will allow Copelme to boost its monthly production volume by 25%, raising it from 50 million to around 62-63 million rolls.

“Building on the success achieved with Valmet’s advanced Perini Constellation™ technology, Copelme continues to invest in Valmet’s technological solutions to strengthen its competitive position in the sector. Specifically, the choice of this line is due to its modularity, sustainability, and safety – qualities that add significant value to support our company’s growth ambitions,” says Rafael Mendoza, Vice President of Copelme.

Founded in 1996 and part of Grupo Mendoza de Inversiones, Copelme S.A. is a Bolivian company specializing in the production and marketing of 42 different tissue paper formats, from roll to fold, in both large and small sizes. The company, with over 650 employees, offers four product lines: Hogar, Nacional, Excelsior, and Institucional serving the consumer, industrial and healthcare markets.

Copelme’s sustainable production is also supported by its RECME (Recicladora Mendoza) operation, which processes used paper and cardboard for the tissue paper industry. This process contributes significantly to resource conservation and waste reduction. As a result, 45% of Copelme’s current output is made from recycled paper, a noteworthy sustainability achievement.

Copelme advances with Perini MyGo

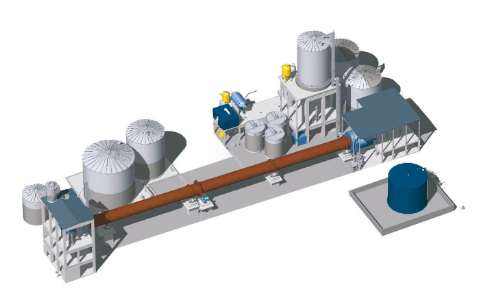

Copelme has established itself as a leader in the tissue paper market through its commitment to continuous innovation, as demonstrated by adopting the Perini MyGo line. The plant specializes in producing toilet and kitchen paper rolls up to 200 mm in diameter, at an operational speed of 600m/min. CE or UL certified, it is a plug & play solution preconfigured to industry standards, ensuring maximum flexibility. One of Perini MyGo’s distinctive features is its modularity: the line’s configuration, equipped with integrated electrical panels and anchored perimeter guards, can be enhanced and expanded with additional components to meet various production needs. This approach minimizes installation time and costs, enabling Copelme to accelerate the market introduction of new products and seize opportunities promptly. Furthermore, Perini MyGo aligns with the client’s values regarding sustainability, incorporating eco-friendly technologies like the Aquabond system, which replaces glue with water in the lamination process to reduce environmental impact. In terms of safety, the electrical panels positioned on individual machines have eliminated the need for junction boxes and relocated PLC I/Os into the electrical panel itself, accessible from outside the line for easier maintenance and diagnostics. Additional benefits include reduced lead times, fast installation, and production area monitoring without direct operator intervention.

Real-Time Efficiency with Valmet Digital Services

Finally, thanks to Valmet’s digital services, Copelme can access real-time reports with data on the line’s productivity and energy consumption, ensuring peak efficiency. This added advantage is significant for the company, which is considering extending this service to other plants for consistent data access.

Rafael Mendoza, Vice President of Copelme, states, “A particularly relevant advantage for us is the presence of a Valmet team in Joinville, Brazil, capable of providing rapid response times to our facility. Moreover, the synergy between our teams, driven by a shared commitment to innovation and strong interpersonal relationships based on shared values, was decisive in choosing the new Perini MyGo technology.” He concludes, “Valmet has been a fundamental partner for Copelme for many years, and with this new project, we reaffirm our commitment to making this partnership even stronger and more enduring.”