Linde Material Handling (MH) launches innovative electric counterbalanced trucks with load capacities up to 2.0 tons. The logistics specialist is replacing its existing range of electric forklifts with a total of 26 new three- and four-wheel truck models with load capacities ranging from 1.0 to 2.0 tons. The new trucks have been designed to offer significant enhancements in ergonomics and performance. In particular, the models with integrated lithium-ion batteries make a significant contribution in this regard.

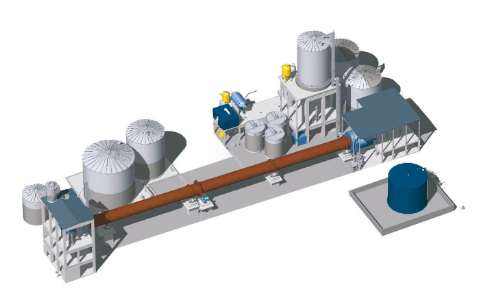

The largest market segment of all industrial truck classes is comprised of three- and four-wheel electric forklifts with a load range of up to two tons. These versatile vehicles are an indispensable asset in a multitude of settings, including beverage stores, distribution centers, food production facilities and the building materials trade. Additionally, they are well-suited for use in paper manufacturing plants and woodworking operations, metalworking shops or chemical production facilities. Applications are extensive, encompassing everything from just a few transport jobs per day to demanding multi-shift operations with loads that are constantly at the maximum load limit. In other applications, the trucks must operate in confined spaces and contend with challenging environmental conditions such as extreme temperatures, dust and dirt.

Two different versions: Linde Xi and Linde E

The latest 12 models in the Linde Xi range feature an integrated lithium-ion battery and load capacities of between 1.0 and 2.0 tons, offering performance and an extended range of applications. An additional 14 variants upgrade the existing standard electric forklifts, the Linde E14 to E20, with load capacities of 1.4 to 2.0 tons and a trough battery. Operators have the option to switch between lead-acid or lithium-ion batteries according to the plug-and-play principle or continue using existing batteries. Furthermore, the E-models have been designed to accommodate fuel cell technology.

Performance, Safety and Digitization

The Linde Xi10 to Xi20 models have seen an increase in efficiency in everyday use, largely due to the combination of a 90-volt lithium-ion battery and a synchronous reluctance motor. The truck can reach 20 km/h in minimal time and offers lifting and lowering speeds that are up to 20 percent higher than the average for competitor trucks. A corresponding thermal management system ensures that the full motor power is consistently available, even under heavy loads and in continuous operation. In the Linde E14 to E20 models, Linde MH relies on proven 48-volt lithium-ion battery technology and maintenance-free asynchronous motors to achieve a high level of performance.

The topic of safety is another key priority. An increasing number of forklift functions, available either as standard or optional features, ensure a high level of protection for drivers and their working environment. The Linde Load Assist system, which automatically adjusts lifting and tilting functions according to the weight of the load and lifting height to prevent tipping accidents, is installed in the new trucks as standard.

Digitization and the seamless networking of processes are also contributing to higher productivity. Wireless data transmission between the truck control and cloud-based applications on a data-protected server enables both predictive maintenance and software updates over the air. Further efficiency increases are anticipated by way of integrating the forklift trucks into digital process chains with warehouse management and forklift control systems.