The pulp drying plant at Bracell’s “STAR” project in Lençóis Paulista, São Paulo, consisting of two identical pulp drying lines (L2A and L2B) supplied by ANDRITZ, has achieved new production world records.

On December 18, 2021, the L2A pulp drying line reached a total output of 4,672.5 air dry tons per day, which is a production world record on a single line. In terms of specific drying capacity, this corresponds to 456 tons per day and meter of working width produced on an ANDRITZ drying line for a sheet width of 10.24 meters.

Moreover, on December 18, 2021, the L2A and L2B pulp drying lines achieved a total of 8,897.4 air dry tons per day on both lines together, which is a new mill-wide capacity world record.

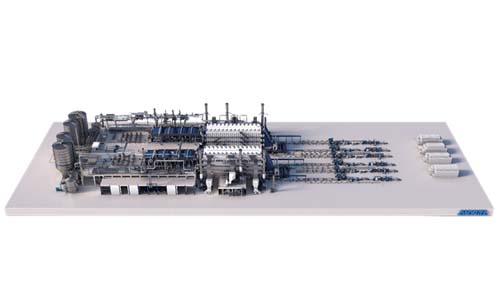

Both records were set during the first four months after start-up. This impressive performance was made possible by ANDRITZ’s leading and proven EvoDry pulp drying system, whose energy-efficient pulp drying is based on the high-capacity Twin Wire Former technology, includes airborne dryers, cutter-layboy and baling lines, and is equipped with the Metris DryQ smart pulp drying solution.

Bracell’s “STAR” project at the mill in Lençóis Paulista is one of the largest and most sustainable pulp mills in the world, meeting the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

These outstanding results are based on the combination of customer and supplier partnership, good plant management and technology as well as excellent planning and implementation.