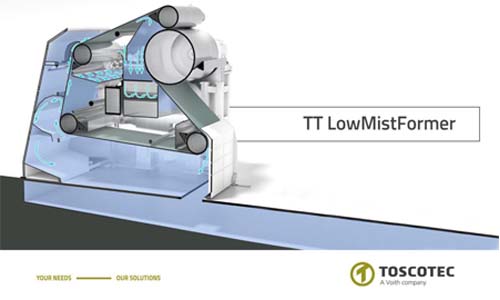

Toscotec has successfully introduced TT LowMistFormer, the latest innovation of the wire section of Crescent Former tissue machines. Originally designed by Voith, the system has been integrated into Toscotec’s design as part of the efficient know-how exchange between Voith and Toscotec following the acquisition. TT LowMistFormer technology has been applied on several AHEAD tissue machines manufactured by Toscotec.

Enrico Raffanti, Toscotec Deputy CTO, says: “TT LowMistFormer improves the runnability of the machine in the key section of paper formation, leading to higher process stability. This new concept is perfectly in line with our mission as manufacturers of advanced technology: developing innovative solutions to boost production efficiency while reducing energy consumption, in order to increase sustainability in paper production.”

Significant mist reduction with zero energy

By creating a screened area in the wire section with an optimized combination of fixed elements, TT LowMistFormer delivers remarkable air, water, and mist flows performance. The contained mist is captured and swiftly carried away through the Venturi effect generated by the jet speed of TT Headbox. The system ensures both a substantial reduction of mist expansion in the environment and its fast removal with zero energy consumption. With TT LowMistFormer the installation of a mist removal system in the forming section becomes unnecessary. This results in the elimination of more than half of the total installed power of a mist removal system, which saves a significant amount of energy.

A key tool to reduce maintenance and improve the working environment

TT LowMistFormer ensures a cleaner and healthier environment around the wire section, which normally produces the highest concentration of mist of the entire tissue line. The system also delivers a significant reduction of dirt build-up on the machine, which leads to a reduction of cleaning and maintenance operations on the production line and on the building. A cleaner environment is also reflected in the increase of machine efficiency and the improvement of working conditions for machine operators.